Designed, Developed and Crafted all In-house

The Process

Design Development

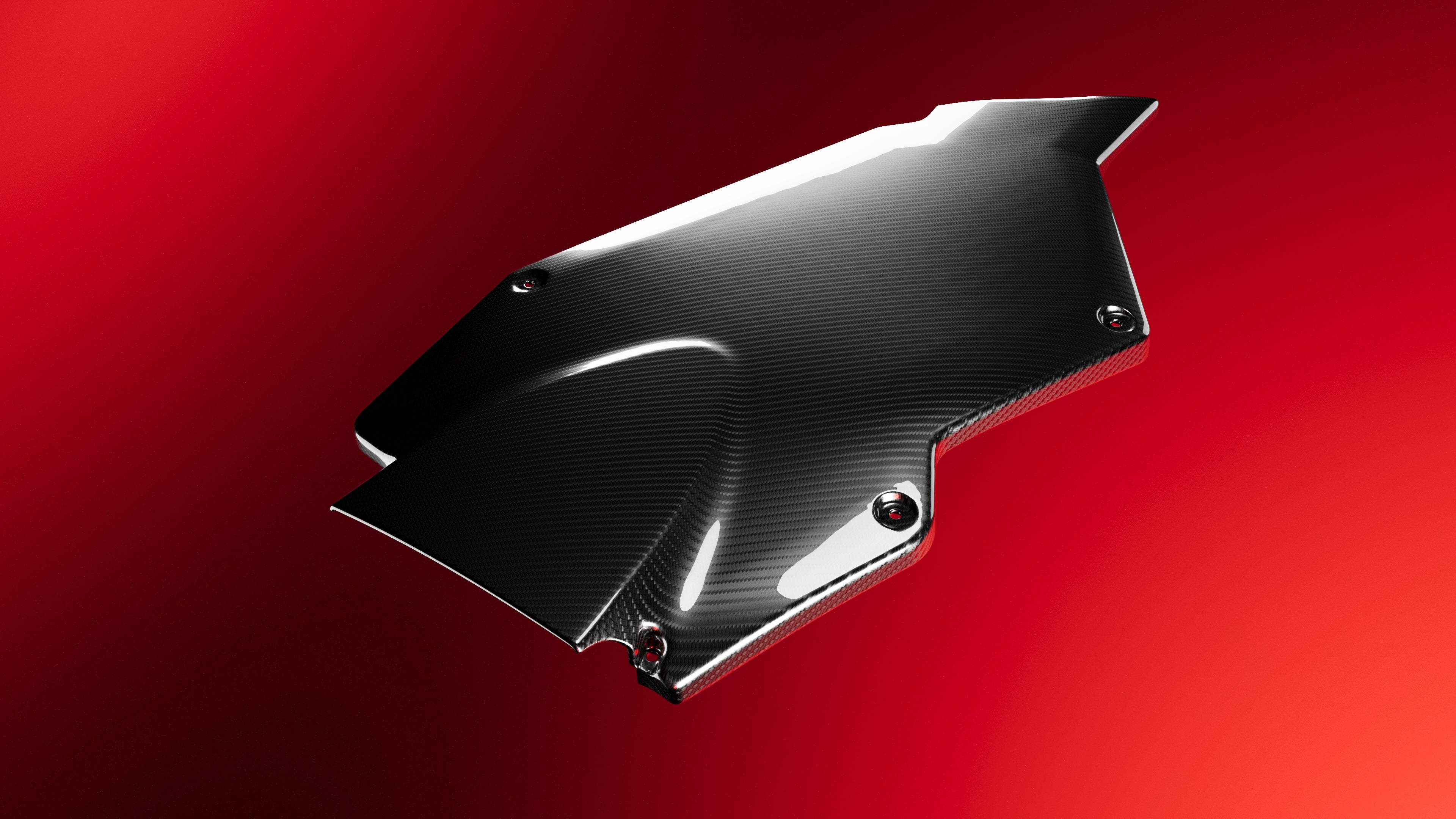

We believe in both form and function. We endeavour to create carbon airboxes that not only deliver maximum performance, but also ensure a striking and unique design.

We start with 3D scan data to ensure accurate fitment to your engine bay. From there we create initial designs balancing package space, aesthetics and performance.

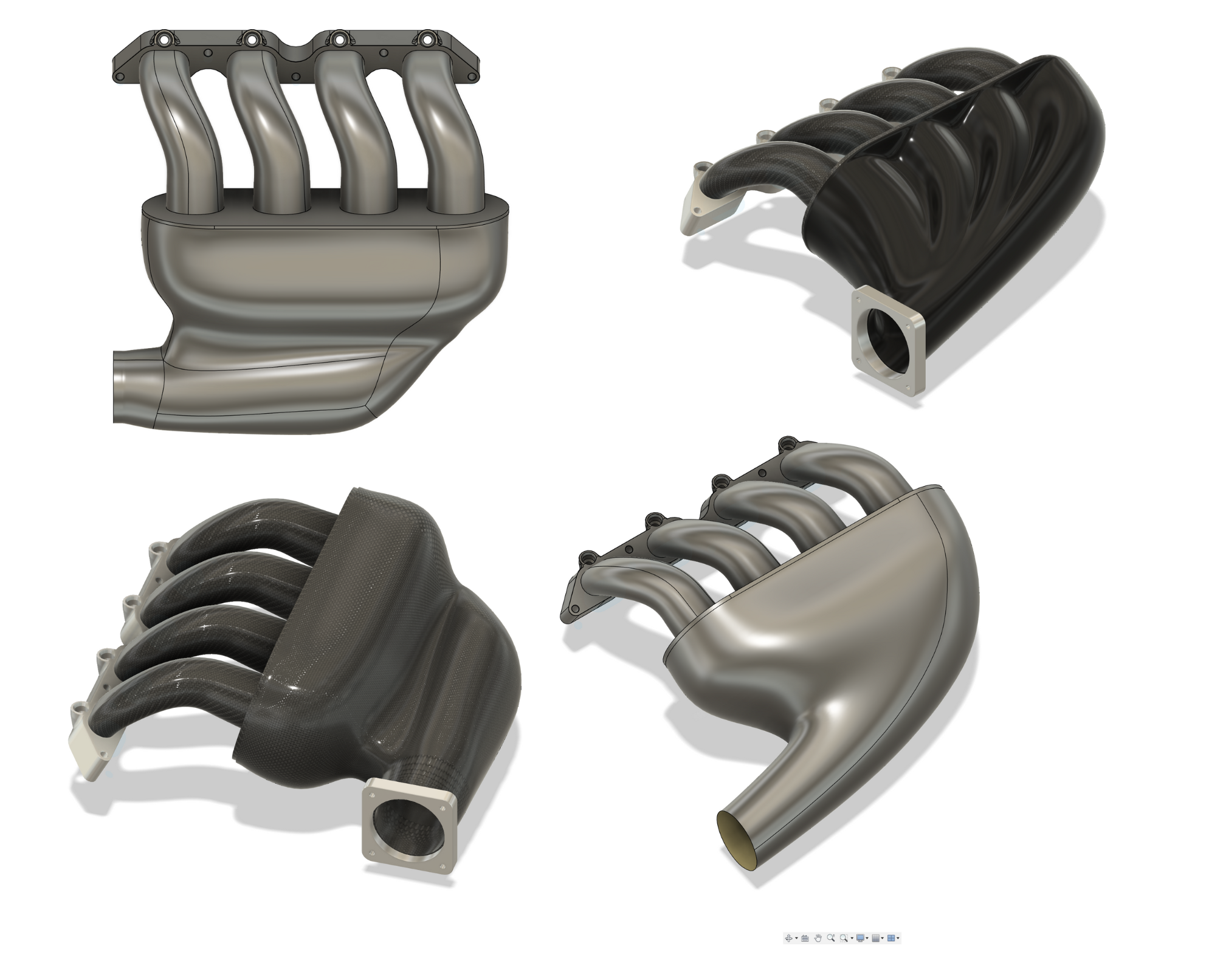

Transient CFD Flow Analysis

With full Computational Fluid Dynamics capabilities, we can study and simulate transient engine conditions at varying loads, RPMs and volumetric efficiencies. In transient simulations, the throttle opening, valve timing and cam duration events are accurately simulated to create a highly realistic intake environment where small details such as reversion pulses can be closely monitored.

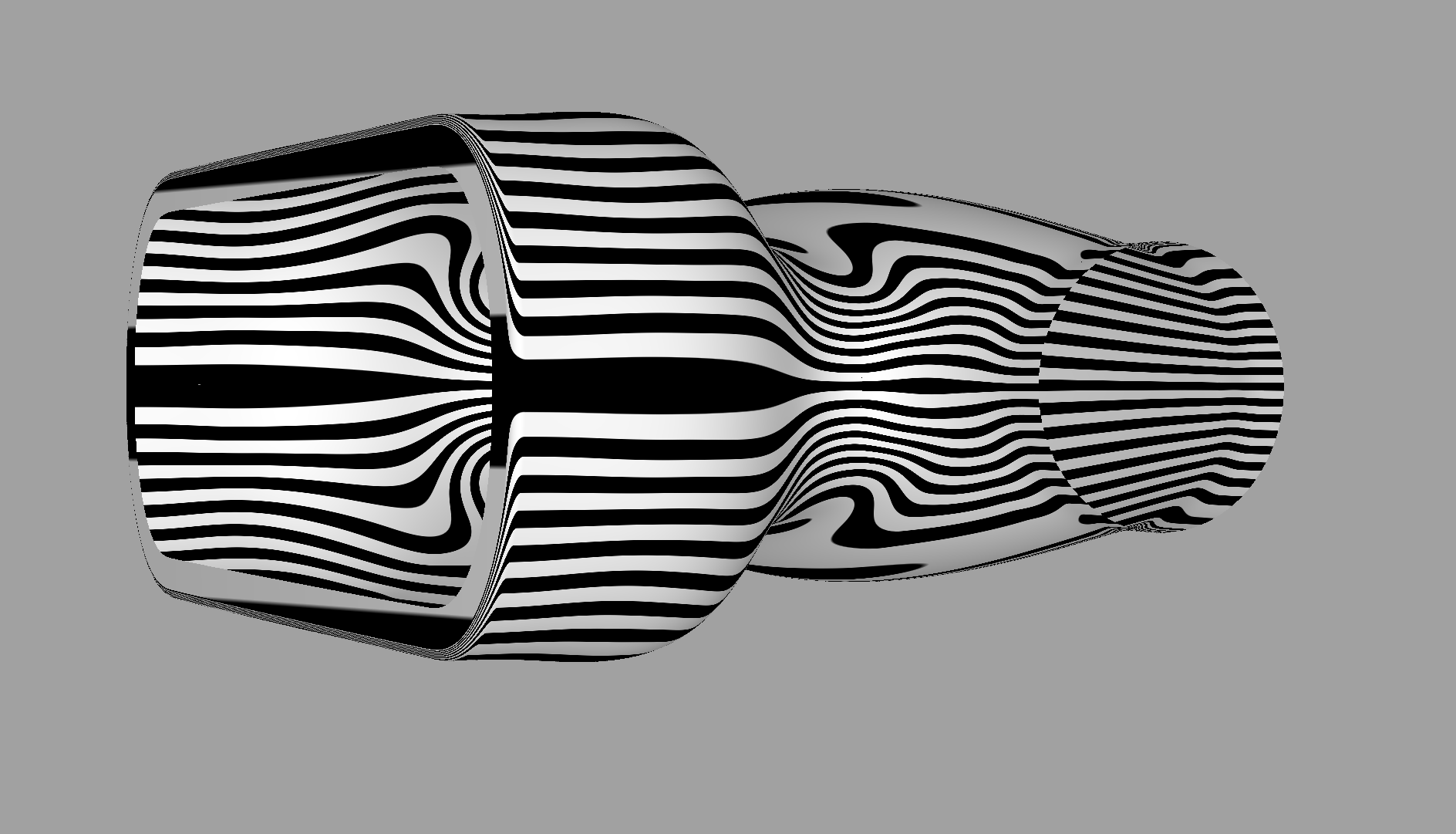

A Class Surfacing

Upon finalising the design for our airbox, we refine the surface quality using Alias, an industry standard software which helps us achieve unparalleled surface reflection quality.

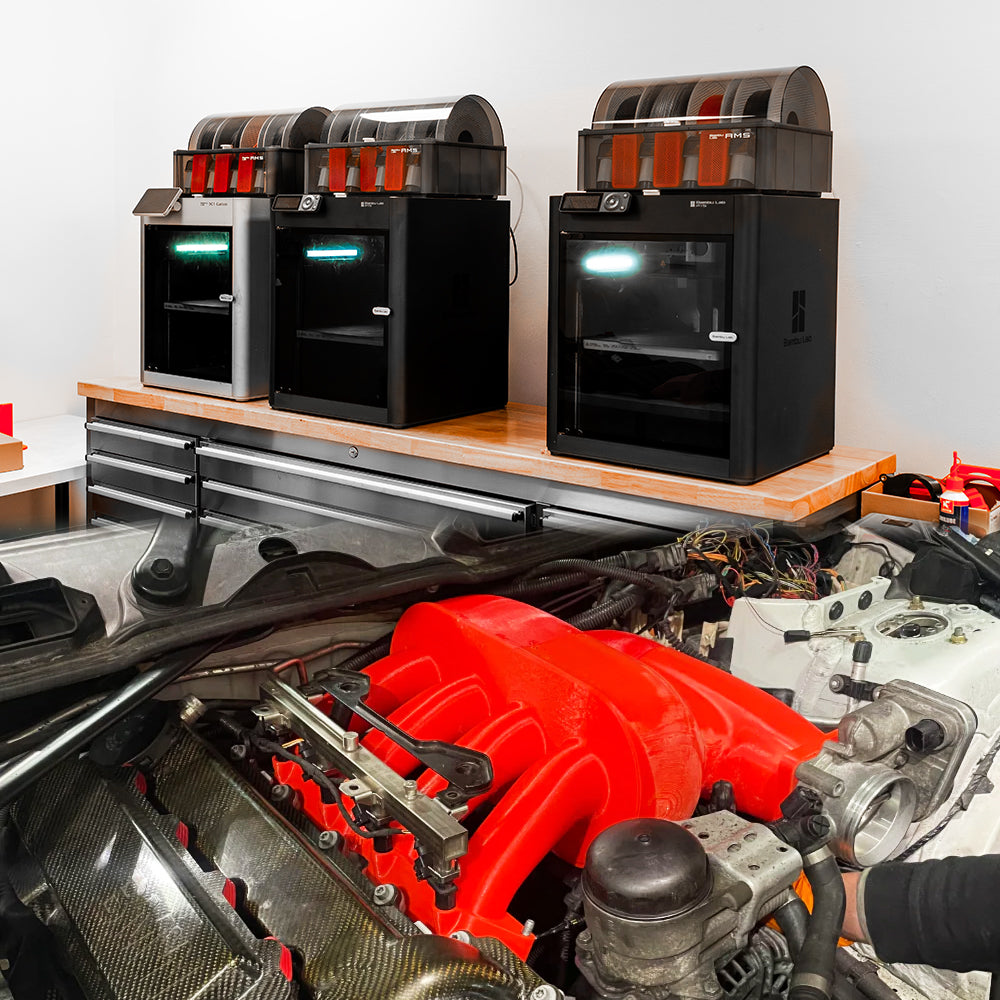

Rapid Prototyping

Using our group of rapid prototyping 3D printers, a full test-fit can be produced in a matter of hours.

Additive Manufacturing

With full carbon fibre additive manufacturing capabilities, it's possible to produce geometries which are impossible through traditional CNC manufacturing or even casting.

Capable of printing 'black aluminium' Polyphthalamide carbon fibre featuring industrial-grade strength comparable to aluminium and temperature resistance up to 227°C.

Dyno Development

Using advanced rapid prototyping with high-temperature filament, it's possible to test multiple iterations in quick succession

We use our in-house dyno from our BMW Workshop to test our prototype. From here we can make sure we have accurate power gain and corroborate our CFD data for accurate results.

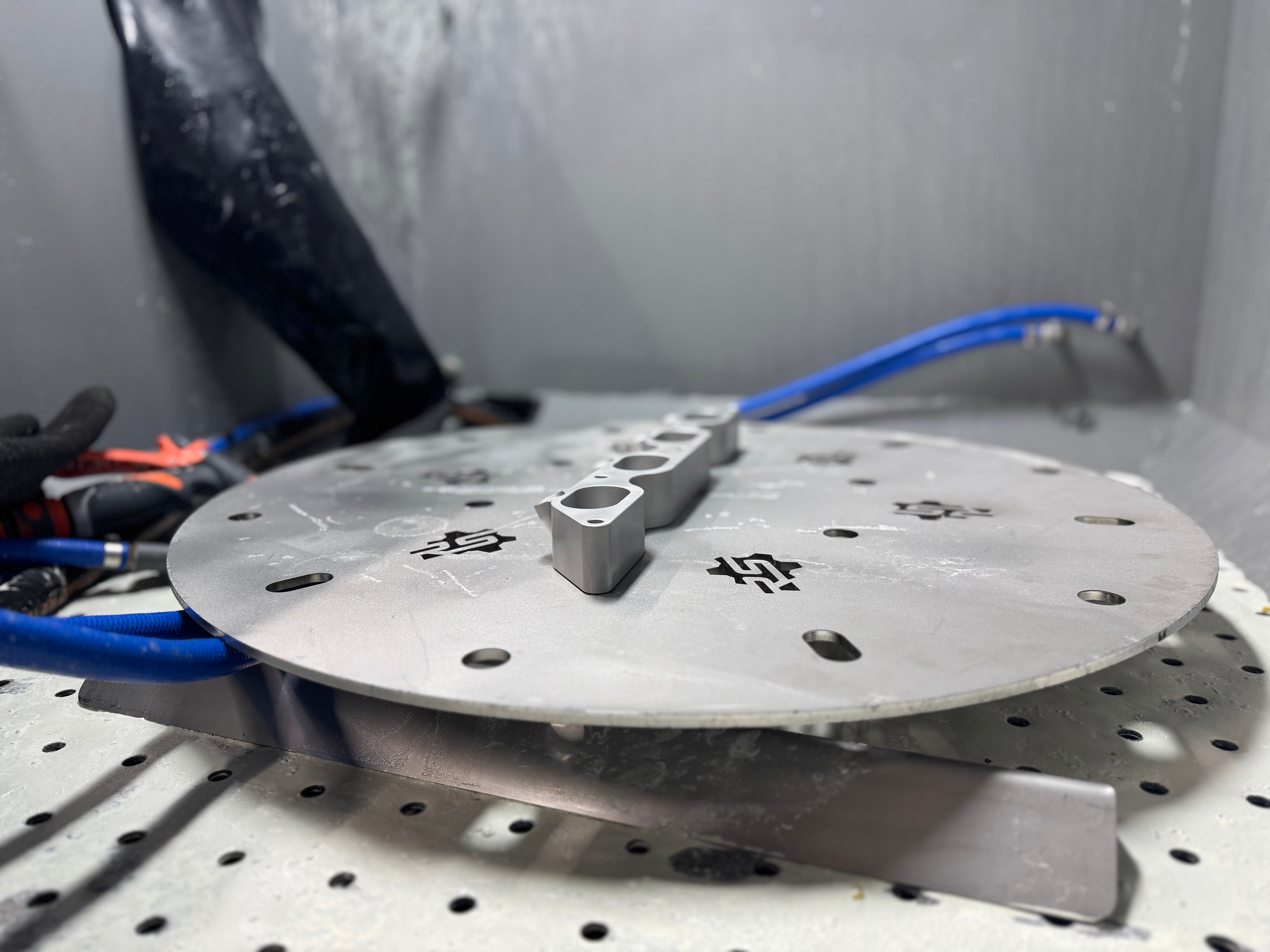

3, 4 &5 Axis CNC Production

Using our 2024 Haas VF-4SS & Simultaneus 5-axis UMC 750, we create prototype parts in both aluminium and titanium as well as our billet composite moulds for pressure-cured prepreg carbon fibre production. With machining accuracy down to 5 microns, 50x smaller than a human hair, components are made at aerospace-grade tolerance.

Vapour Bead Blasting

Using industrial-grade, small-diameter Ceramic media, the 2024 RS-Pro cabinet produces flawless surface finishes, creating even, high-shine satin parts in both Aluminium and Titanium.

Colour Anodising

All flanges are clear anodised for excellent long-term corrosion, chemical and abrasion resistance. With Atelier, clients can select full Type II colour anodising through Atelier in various high-contrast shades. With a coating thickness of up to 25 Microns, long-term durability and UV resistance is ensured.

The Key Members

The Vision

Founded by Co-owners Marijke and Daniel, Carraero started off as nothing more than a dream to shake up the stagnant automotive accessory space. With storied backgrounds and deep connections to the BMW brand: Marijke in Motorsport with JC Racing & AMSpeed, and Daniel with engine development and tuning with BDS Motorsport. The mission statement was clear: technically innovative, highly bespoke composite components with unrivalled quality and individualism.

Senior Production Engineer

Mark Roper

With a comprehensive background in programming and operating some of the world's finest 3, 4 & 5-axis CNC machines with HyperMILL, Mark is expertly qualified to tackle the most challenging and advanced projects. With previous work at Gardner Aerospace and touring-car specialists Neil Brown Engineering, Mark is highly skilled in designing, overseeing and producing a near-limitless range of components, completely in-house.

Process & Manufacturing Supervisor

Liam Autumn

With experience in a wide range of production disciplines from additive 3D manufacturing, anodising, carbon fibre lay-up and multi axis CNC machining, Liam is expertly qualified to assist and manage all areas of the production cycle.

Design Engineer & Visulisation Artist

Oscar Ingle

Oscar is our specialist design engineer and vis artist, having previously worked at Futura Design, specialising in automotive conceptual design and prototype manufacturing. With a deep love for cars and engineering, Oscar continues to explore cutting edge design trends and technologies, always contributing fresh ideas and bringing them to life.

Creative Marketer & Videographer

Jason Cutts

Jason is our in-house creative, responsible for sharing our creations with the world via photo, video, social media and more. With experience documenting automotive culture, capturing cars in action and steering brands, he's always at hand to provide a creative solution.

Customer Advisor

Nuala Flynn

Ever friendly and approachable, Nuala is always on hand to assist with customer enquiries and keep things running smoothly here at Carraero. With experience building rapport with customers around the world, Nuala is a fantastic addition to the team and will no doubt greet you with a smile.

Composite Laminator & Anodiser

Awais Mahmood

Awais is our in-house composite and anodising technician with a BSc in mechanical engineering and extended experience with pre-preg materials and carbon mould production. Each aluminium component is precisely anodised completely in-house.

Development Specialist

Bruno Da Silva - BDS Motorsport

With an uncompromising eye for effecient power and airflow gain, Bruno has mastered his craft of improving a huge range of engines and intake systems. His extensive knowledge of engine tuning sets him apart, providing Carraero with invaluable insight and exptertise.

Commission Artist

Debbie Baxter

Debbie is a talented fine-art and digital artist who works closely with clients who desire something even more bespoke and stand-out. Creating completely unique plenum graphics and artworks, she can transform any engine-bay and offer the ultimate in personalisation.

Explore Atelier Commission